Mint Turbines Luke K. Employee Spotlight

In this interview, Luke Keigley, a T700 Field Service Engineer at Mint Turbines, shares his journey from the Air Force to his current role, providing insights into his dynamic workdays and proudest moments, including working on the B1 Bomber project. As a history buff, he reveals his favorite aircraft and discusses his hobby of building model aircraft. Luke joined the team in 2023 and has shown his skill and attention to detail throughout his time at Mint Turbines.

In this interview, Luke Keigley, a T700 Field Service Engineer at Mint Turbines, shares his journey from the Air Force to his current role, providing insights into his dynamic workdays and proudest moments, including working on the B1 Bomber project. As a history buff, he reveals his favorite aircraft and discusses his hobby of building model aircraft. Luke joined the team in 2023 and has shown his skill and attention to detail throughout his time at Mint Turbines.

What is your title at Mint Turbines, and how long have you worked there?

Hi, I am Luke Keigley, a T700 Field Service Engineer at Mint Turbines. I have had the pleasure of working at Mint Turbines for 10 months.

How did you start in the aerospace industry and at Mint Turbines? What is your educational background?

I got started by joining the Air Force back in 2003 and became a propulsion specialist for turboprops and turboshafts. And that’s pretty much how I got into this position. Then, my education is up to an associate’s degree through the Air Force.

What does your typical workday look like at Mint Turbines?

Day to day, my job kind of changes. One day, I might be tearing into an engine, doing compressor blending on the T700, changing out different components, and things like that, or I might be working on helping them get the test cell up and running so we can start running and testing engines. I like that it’s always something new.

What is your favorite thing about working at Mint Turbines?

I would say kind of starting something from scratch. Starting from the ground up and basically trying to get everything squared away and ready to start doing operations is really satisfying to me.

What is one of the most memorable projects you’ve worked on in your career?

I’d have to say one of the proudest things that I’ve worked on now throughout my career would be working on the B1 Bomber. That was the first time that we ever launched operational B1s from South Dakota to carry out a mission in Libya. I’ll always remember that we were the first people to do that. I worked on the project for more than four years.

In your opinion, what sets Mint Turbines apart from other companies in the industry when it comes to turbine maintenance and field services?

The shop is very clean, very organized and a great group of competent individuals that know what they’re doing and send out a very quality product.

What is your favorite aircraft?

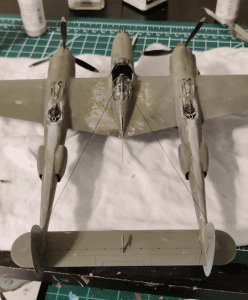

That’s kind of a tough one because I go back to some really old aircraft because I’m a very big history buff. But my personal favorite aircraft of all time would have to be the P-38 Lightning from World War II. It’s a very unique fighter. It’s a twin-engine, twin-boom design and was designed by Lockheed Martin.

Looking back at this year, what is one of your favorite achievements or memories from Mint Turbines in 2023?

I’d say seeing the test come together. We saw it as a bunch of wires and concrete at the beginning. Now it’s an actual working and viable test cell, which is neat to work with.

What do you enjoy doing when you’re not at work?

When I’m not at work, I enjoy spending time with my wife, cats and working on models. I like making model airplanes, cars, trucks, things like that.

What a busy year 2023 was for Mint Turbines! We attended several shows, and it was great to see all our customers. We’re looking forward to 2024 and all the exciting events.

What a busy year 2023 was for Mint Turbines! We attended several shows, and it was great to see all our customers. We’re looking forward to 2024 and all the exciting events. EAA AirVenture Oshkosh 2023, held from July 24-30 in Oshkosh, Wisconsin, was a week filled with aviation innovation, thrilling air shows, informative displays and insightful speakers. Mint Turbines was honored to attend and support this year’s event.

EAA AirVenture Oshkosh 2023, held from July 24-30 in Oshkosh, Wisconsin, was a week filled with aviation innovation, thrilling air shows, informative displays and insightful speakers. Mint Turbines was honored to attend and support this year’s event. The PT6 engine is a renowned gas turbine engine operating on Jet A fuel, consisting of modular components that function through air. Its standout features lie in its exceptional reliability and popularity, provided it receives regular maintenance. What sets the PT6 engine apart from its counterparts are its various models, sizes and horsepower options, catering to a wide range of aircraft types. Its low maintenance requirements and remarkable durability ensure a long lifespan, making it a preferred choice among aviation professionals.

The PT6 engine is a renowned gas turbine engine operating on Jet A fuel, consisting of modular components that function through air. Its standout features lie in its exceptional reliability and popularity, provided it receives regular maintenance. What sets the PT6 engine apart from its counterparts are its various models, sizes and horsepower options, catering to a wide range of aircraft types. Its low maintenance requirements and remarkable durability ensure a long lifespan, making it a preferred choice among aviation professionals. This quarter, we had the opportunity to sit down with Gilbert Palacios, a seasoned Field Service Engineer at Mint Turbines. With a 16-year tenure, Gilbert graciously shared insights into his career and experiences at Mint Turbines.

This quarter, we had the opportunity to sit down with Gilbert Palacios, a seasoned Field Service Engineer at Mint Turbines. With a 16-year tenure, Gilbert graciously shared insights into his career and experiences at Mint Turbines. In July, Mint Turbines had the honor of being showcased in the HAI Member Spotlight by Rotor Media.

In July, Mint Turbines had the honor of being showcased in the HAI Member Spotlight by Rotor Media.

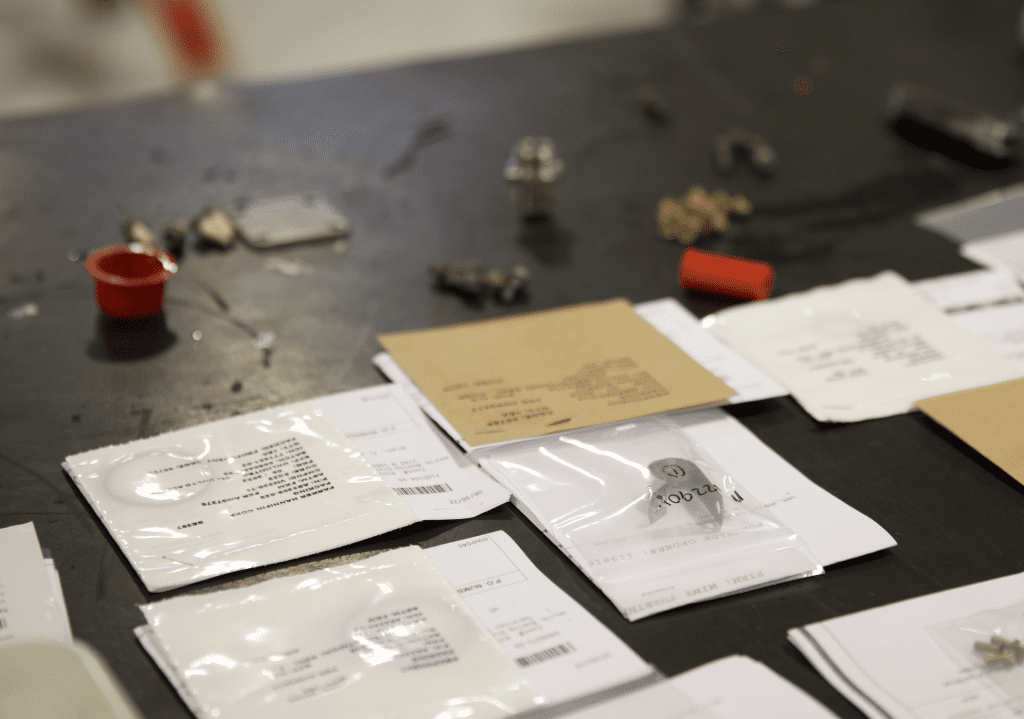

Jason McNeese is a crucial member of Southwest Fuel Systems, a sister shop of Mint Turbines. In 2019, Southwest Fuel Systems made the strategic decision to relocate from Tucson, AZ to Stroud, OK, where they moved into the same building as Mint Turbines. This move was aimed at taking advantage of the synergies that naturally arise when two complementary operations are in close proximity to each other. Southwest Fuel Systems is Triumph certified on the Ozark T53 engine Fuel controls, governors and RR250 engine HMUs. Here at Mint, we value our partnership with Southwest Fuel Systems and the people like Jason that ensure that quality and safety standards are met in the shop. Learn more about Jason in with Q&A below.

Jason McNeese is a crucial member of Southwest Fuel Systems, a sister shop of Mint Turbines. In 2019, Southwest Fuel Systems made the strategic decision to relocate from Tucson, AZ to Stroud, OK, where they moved into the same building as Mint Turbines. This move was aimed at taking advantage of the synergies that naturally arise when two complementary operations are in close proximity to each other. Southwest Fuel Systems is Triumph certified on the Ozark T53 engine Fuel controls, governors and RR250 engine HMUs. Here at Mint, we value our partnership with Southwest Fuel Systems and the people like Jason that ensure that quality and safety standards are met in the shop. Learn more about Jason in with Q&A below.