July HAI Member Spotlight

In July, Mint Turbines had the honor of being showcased in the HAI Member Spotlight by Rotor Media.

In July, Mint Turbines had the honor of being showcased in the HAI Member Spotlight by Rotor Media.

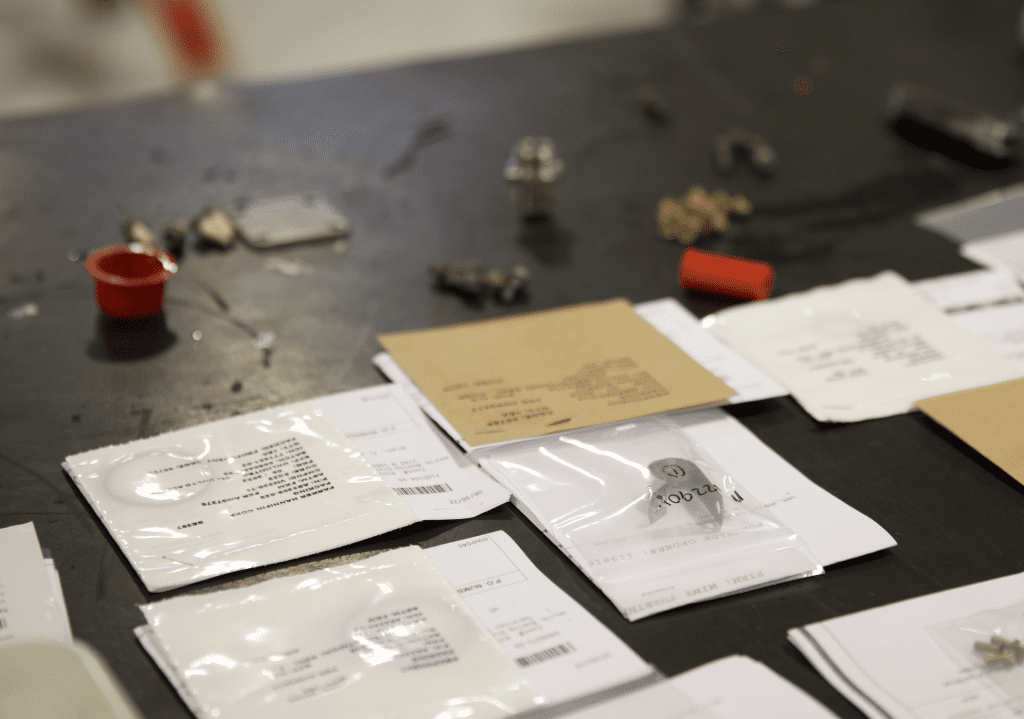

‘Mint Turbines, LLC, of Stroud, Oklahoma, offers a wide range of capabilities for helicopter engine maintenance, repair, and overhaul (MRO), as well as testing and other services. Achievements of the MRO center include serving as an FAA/European Union Aviation Safety Agency (EASA) Part 145 repair station, an authorized Ozark Aeroworks T53 engine service center, an independent Pratt & Whitney Canada (PW&C) PT6A and PT6T maintenance center, including the correlation of the PT6A test cell, and a General Electric Aviation-licensed T700 restricted-category MRO center. Leading the company is a seasoned team of MRO professionals, each with an average of more than 20 years of experience with engines.’

Read the rest of the story here.

Jason McNeese is a crucial member of Southwest Fuel Systems, a sister shop of Mint Turbines. In 2019, Southwest Fuel Systems made the strategic decision to relocate from Tucson, AZ to Stroud, OK, where they moved into the same building as Mint Turbines. This move was aimed at taking advantage of the synergies that naturally arise when two complementary operations are in close proximity to each other. Southwest Fuel Systems is Triumph certified on the Ozark T53 engine Fuel controls, governors and RR250 engine HMUs. Here at Mint, we value our partnership with Southwest Fuel Systems and the people like Jason that ensure that quality and safety standards are met in the shop. Learn more about Jason in with Q&A below.

Jason McNeese is a crucial member of Southwest Fuel Systems, a sister shop of Mint Turbines. In 2019, Southwest Fuel Systems made the strategic decision to relocate from Tucson, AZ to Stroud, OK, where they moved into the same building as Mint Turbines. This move was aimed at taking advantage of the synergies that naturally arise when two complementary operations are in close proximity to each other. Southwest Fuel Systems is Triumph certified on the Ozark T53 engine Fuel controls, governors and RR250 engine HMUs. Here at Mint, we value our partnership with Southwest Fuel Systems and the people like Jason that ensure that quality and safety standards are met in the shop. Learn more about Jason in with Q&A below.

Mint Turbines is an industry-leading FAA/EASA certified Part145 Repair Station, providing world-class service. For over 40 years Mint Turbines has provided maintenance, repair, and overhaul services for operators worldwide. Mint can provide professional service from a team of experienced technicians with an average of 20 years combined experience, industry-leading customer support and a quality assurance team.

Mint Turbines is an industry-leading FAA/EASA certified Part145 Repair Station, providing world-class service. For over 40 years Mint Turbines has provided maintenance, repair, and overhaul services for operators worldwide. Mint can provide professional service from a team of experienced technicians with an average of 20 years combined experience, industry-leading customer support and a quality assurance team.

Wow! What a great year 2022 was for Mint Turbines! With the world fully opened back up, we were able to attend shows again and, most importantly, we embraced the opportunity to get out and see our customers. We enjoyed attending HAI and AAAA in 2022 because we were able to see all of our old and new customers. We’re looking forward to 2023 and all of the exciting events to come.

Wow! What a great year 2022 was for Mint Turbines! With the world fully opened back up, we were able to attend shows again and, most importantly, we embraced the opportunity to get out and see our customers. We enjoyed attending HAI and AAAA in 2022 because we were able to see all of our old and new customers. We’re looking forward to 2023 and all of the exciting events to come.