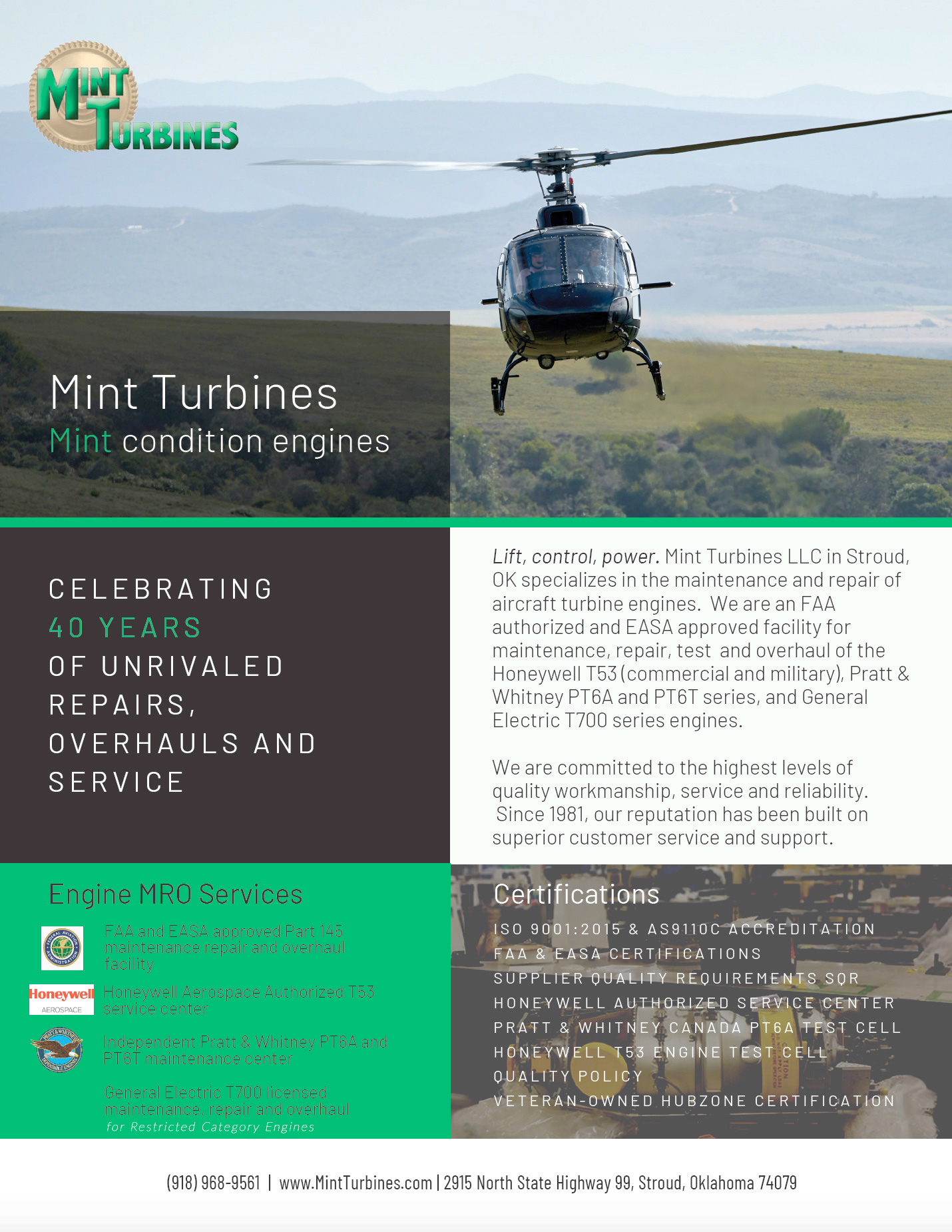

Mint Turbines Employee Spotlight: Randy Plunkett

Randy Plunkett, Test Cell Supervisor and Production Lead

Randy Plunkett, Test Cell Supervisor and Production Lead

Randy Plunkett started at Mint Turbines nearly 23 years ago with no experience after the 1999 tornado destroyed the grocery distribution facility he worked at. Since then, Randy has touched all aspects of the engines at Mint Turbines from disassembly and assembly to now serving as the Test Cell Supervisor and Production Lead. Read more about Randy in the Q&A below.

What do you do at Mint Turbines and how long have you worked here?

I am currently a Test Cell Supervisor and Production Lead. In June, I will have 23 years on.

The Test Cell is the last place the engine goes – it has to be in great shape or it’s not leaving.

How did you get started in aerospace and at Mint Turbines?

I worked as a grocery distributor in Stroud that was blown away by the 1999 tornado before getting hired at Mint Turbines. I didn’t have any experience but had friends here that helped get me on. I was trained and started out in the disassembly and tear down area.

How have you grown at Mint Turbines?

I started in disassembly before moving to assembly where I learned how to build engines. In 2011, I moved to the Test Cell. I like to be able to do a little bit of everything, so I still build engines and sometimes go tear them down, too. I like to be well rounded.

What is your favorite thing about working at Mint Turbines?

Not a lot of people work on aircraft engines, it’s a really big deal to me. It’s a job I don’t mind coming to everyday.

Tell us about a memorable time at Mint Turbines in your nearly 23 years.

I think seeing the company grow is a big deal – we’ve been through growth with the T53 line and have built our Test Cell from the ground up. It was neat watching that all come together.

What are you doing when you’re not at Mint Turbines?

I have a wife, three kids and three grandkids and I love to hunt deer. I also work part-time doing drywall when I’m not hunting.

Any final thoughts?

I just really think this is a great place to work. I mean, if I didn’t like it, I wouldn’t have stayed here 23 years.

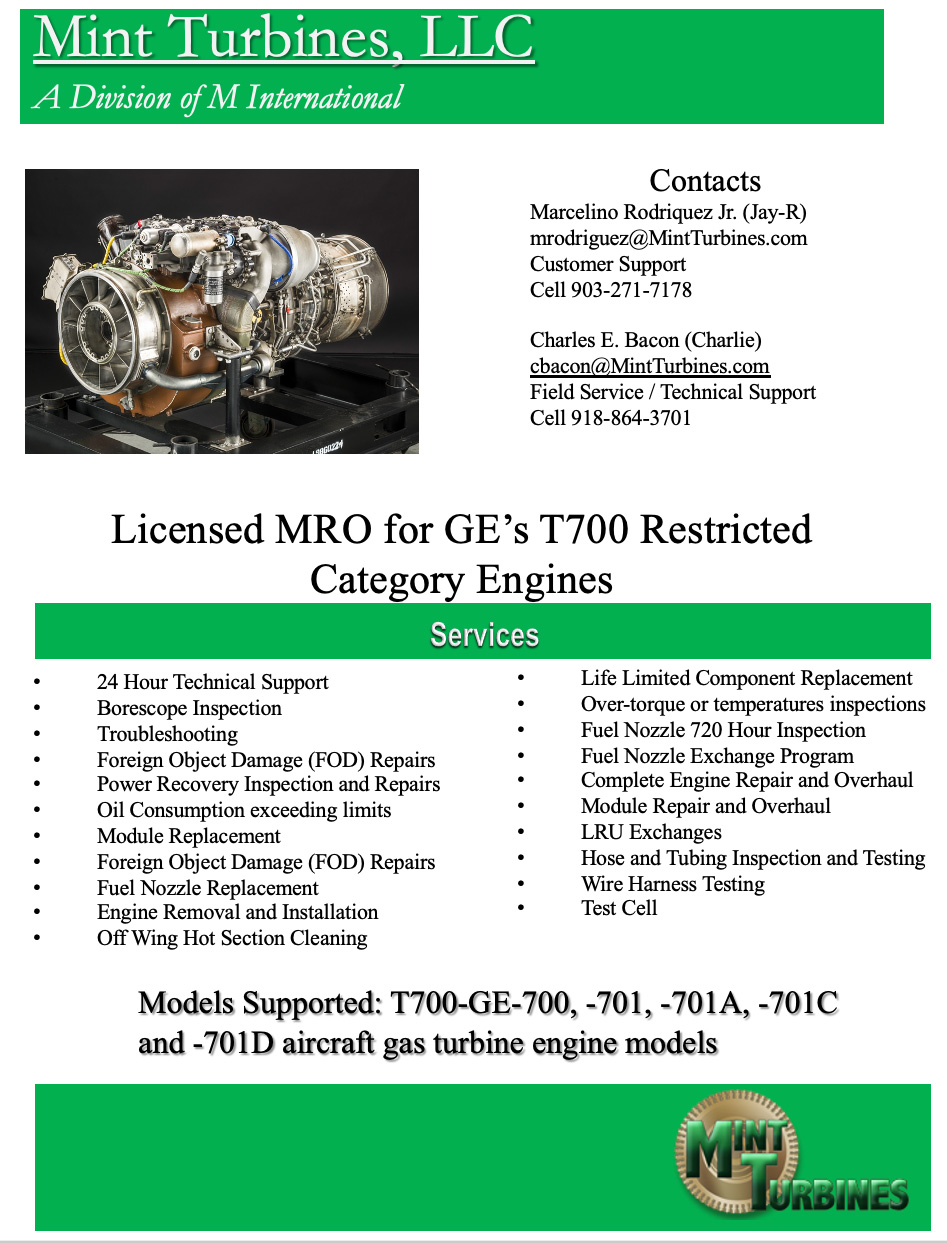

The second week in February, Charlie Bacon conducted a T53 Engine 40-Hour Initial FAA Accepted Inspection Authorization Renewal Course. This hands-on refresher training course, taught at our facility, focused on many different areas, including Basic Turbine Theory, Trouble Shooting Analysis, Design and Output Capabilities, Engine Components, Fuel System, Scheduled Maintenance, Unscheduled Maintenance, Minor Repairs, Service Bulletins and Airworthiness Directives.

The second week in February, Charlie Bacon conducted a T53 Engine 40-Hour Initial FAA Accepted Inspection Authorization Renewal Course. This hands-on refresher training course, taught at our facility, focused on many different areas, including Basic Turbine Theory, Trouble Shooting Analysis, Design and Output Capabilities, Engine Components, Fuel System, Scheduled Maintenance, Unscheduled Maintenance, Minor Repairs, Service Bulletins and Airworthiness Directives.